No products in the cart.

X-carriage assembly

here, all same as workbee instructions

Items you need for this step:

Attach 6 V wheel assemblies to the Z plate with 30mm screws – and at one side of the plate, use 6mm spacers with a precision shim, whereas at the other side, use eccentric spacers with a precision shim:

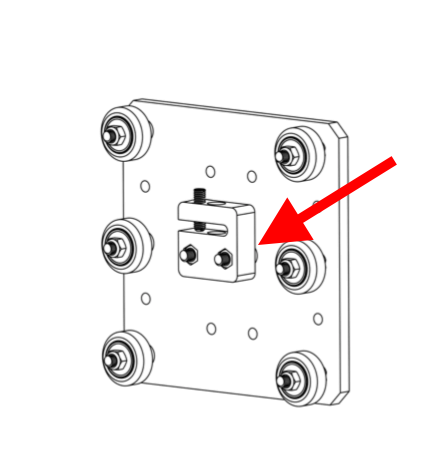

Then, attach the Z axis nut block:

Use 25mm or 30mm screws to attach the nut block – and position 3mm spacers between the nut block and the Z plate, as highlighted with the red arrow. Use M5 lock nuts to secure the screws and nut block.

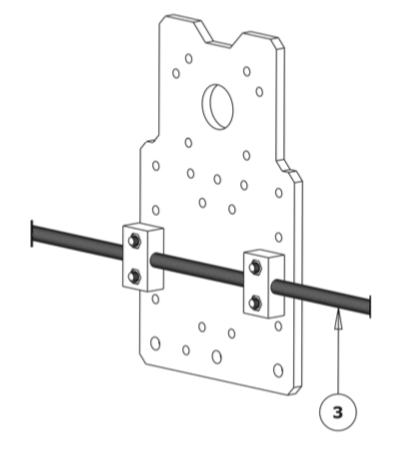

Now, we shall attach the nut blocks for the X axis leadscrew:

Use 25mm screws to attach the nut blocks – there is M5 tapping in the nut blocks:

Attach the wheels and X front plate now , in the same way as you did for the Y axis plates:

Now is also a goo moment to attach the Z axis limit switch as it’s easier to reach now:

And attach the Z plate to the X front plate with 20mm screws:

And add the Z axis extrusion:

And the Z axis motor and leadscrew:

With 40mm spacers and 50mm screws: